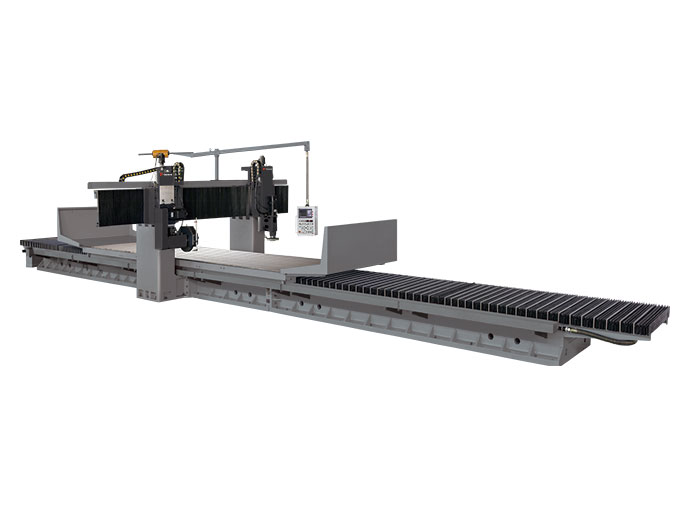

Massive and Rigid Construction: The GP series double column surface horizontal grinding machine by Top-One is meticulously designed with a massive and rigid construction, ensuring exceptional precision in grinding extra-large workpieces.

Versatile Grinding Heads: Standard equipment includes a horizontal grinding head, with an optional vertical wheel head available upon request, providing versatility in machining options.

High Precision Z-Axis Downfeed: The machine features a high precision Z-axis downfeed capable of reaching 2 µm, meeting the most stringent requirements for high accuracy grinding.

With a massive and rigid construction, the GP series double column surface grinder from Top-One is designed and built for precision grinding for extra-large work pieces. This series of machine is equipped with a horizontal grinding head as standard equipment, and a vertical wheel head is available upon request. High precision Z-axis downfeed can reach 2 µm, which will fully meet high accuracy grinding requirements.