Features

Ladder Type Linear Ways On Beam

- The linear ways on the beam are supported by a ladder structure that upgrades stability of the spindle head.

-

The heavy duty roller type linear ways combined with three slide blocks on each linear way guarantee greater rigidity on they-axis.

Auto-Index Universal Milling Head

-

High rigidity , high torque and high speed. The head's B/C axis with accuracy indexing positions of 2.5*2.5 degrees is capable for large work-piece , precision and complicated mold.

-

UAG can accomplish 5 face and multi face machining work at one-time work-piece setup which can increase accuracy and effecincy of machining. It would be your best investment for increase producton capability.

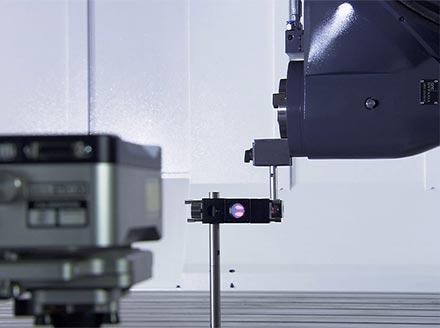

Laser Inspection On Three Axes

-

Each machine is inspected using an advanced laser unit for calibration. The laser unit is applied for inspecting and calibrating the screw pitch error, backlash, positioning accuracy and repeatability.

-

The precision inspection may ensure the dynamic and static ability of the machine and its machining accuracy.

Cutting Capacity

Face Milling

| Cutting tool | Ø125 x 8t |

| Tangential speed | 295.35 m/min |

| Cutting width | 120 mm |

| Cutting depth | 4 mm |

| Cutting feed rate | 140 mm/min |

| Cutting amount per tooth | 0.27 mm |

| Material removal rate | 756 mm |

| Workpiece material | S45C |

| Spindle load | 80% |

*Note: The above cutting test values are for reference only. The values may vary with customers cutting conditions.

Drilling

| Tool diameter | Ø90 mm |

| Tool material | Tungsten Carbide |

| Cutting depth | 100 mm |

| Cutting feed rate | 5 mm/min |

| Workpiece material | SUS304 |

| Spindle load | 48% |

*Note: The above cutting test values are for reference only. The values may vary with customers cutting conditions.

End Milling

| Cutting tool | Ø32 x 8t |

| Tangential speed | 158.6 m/min |

| Cutting width | 6 mm |

| Cutting depth | 20 mm |

| Cutting feed rate | 120 mm/min |

| Cutting amount per tooth | 0.21 mm |

| Material removal rate | 187 cc/min |

| Workpiece material |

Ø125 x 8t |

| Spindle load |

65%

|

*Note: The above cutting test values are for reference only. The values may vary with customers cutting conditions.

Specifications

Standard Accessories

- Nicolas Correa UDG

- Halogen work light

- Controller operation manual and electric circuit drawing

- Operation and maintenance manual

- Service tool

- Leveling bolts and blocks

- RS-232 interface

- Program finished warning lamp

- Automatic power-off device

- Air gun for removing chips

- Forced automatic lubrication system

- Air system

- Z-axis hydraulic counter-balancing system

- Nitrogen gas counter-balancing system

- Spindle oil cooler

- Coolant pump and tank

- Crawler chip conveyor with chip bucket

- Ship augers (at both sides)

- Semi-enclosed splash guard

- Machine accuracy inspection report

Optional Accessories

- Auxiliary tool stand

- NC rotary table

- Automatic tool setting device

- Computerized scanning imitative system

- Liner scale feedback

- Oil water separating tank

- Coolant through spindle